Adapt the downstream process

to meet your production goals

Fermentation, bio-based chemicals, and biomass valorization are key areas in rapid growth and evolution for a sustainable future.

It covers also a wide variety of topics, with numbers of overlaps:

- Fermentation is typically defined as processing through the help of microorganism. Key product can be the microorganism itself (yeast, fungi), the transformed feed material (cheese, yogurt, ..) or something produced by the micro-organism (amino acid, organic acid, protein, …) that further needs to be isolated and purified.

- Bio-based chemicals is here linked to specifically non-food applications produced from renewable (our low Carbon impact) raw materials. It can come from various biomasses (agricultural, wood, waste) as opposed to petrochemical raw material, for a same use or a similar use of the end product.

- Biomass valorization is specifically linked to the field of renewable raw material from crops or specific portions in competition with food valorization. It can covers agricultural residues, wood or cellulosic materials and various waste streams. It is a pilar of circular bio-economy.

Large diversity of topics and numbers of overlaps between them. Numbers projects are focusing on biomass valorization for producing bio-based products through fermentation!

Latest innovations, from biotechnology technologies to digitalization, and investors’ interests on the potential offered by numbers innovations, make this sector evolving very fast.

Intense worldwide collaboration between talents, cutting edge technologies & data driven approaches, fast & efficient R&D and up-scaling services are key to successful development of promising and impactful products.

Efficient & economic purification is part of every roadmap, at every scale:

- Lab and modelling.

- First grams to first tons of products.

- Industrialization and upscaling challenges.

- Demo to industrial assets.

At Applexion, we use our cutting edge R&D facilities and proprietary modelling services, we apply our development and scale up methodology to build fast, together, robust purification solutions.

Our Design & Build offer supports your development from the lab to the start-up of your demo or industrial unit.

Supported by +50 years worldwide application experience, our top-qualified teams of scientists and experts can quickly support your specific needs for producing high quality products, with most demanding standards of reliability and safety. Applexion can design and supply most efficient solutions, support you operating them at optimal performance level, meeting with your expectations for efficiency and profitability, targeting lowest possible carbon footprint.

Our Upgrade and Revamp services will, hand in hand, make sure existing equipment are not left apart from reuse opportunities in the production of new products.

Organic Acids

Organic acids

production

Improve the production process of your factory.

Organic acids can be produced by fermentation (fungi or bacteria). Depending on the reaction conditions, the organic acid will be in acid or salt form, influencing the downstream process.

Applexion has developed optimized purification solutions for organic acids, based on combination of cost effective and as much as possible sustainable technologies. Our objective is to provide the optimum method of purification for downstream processing.

Citric acid

The production of citric acid is mostly based on a fermentation process from different sources of carbohydrates (molasses or starch based media). Once the fermentation process achieved, the citric acid is extracted and purified to match with quality standards, whether food, chemical or pharmaceutical.

The gypsum free separation, developed and patented by Applexion™, offers a very efficient and environmentally-friendly alternative for the purification of organic acids using Applexion™ SC technology and the principle of acid retardation.

This process can be adapted to any organic acid produced under low pH conditions.

- Less chemical consumption:

– No CaCO3 required with very little use of H2SO4.

– Reduced need for activated carbon and ion exchange regeneration chemicals.

- Less waste:

– No gypsum waste.

– Reduced liquid waste.

- Better yield:

– 97% using Applexion™ SC for broth.

– 98.5% using Applexion™ SC for mother liquor.

Lactic acid

Lactic acid can be separated from fermentation broth by several purification techniques. Optimizing lactic acid production methods can lead to advancements in various fields, from food production to biotechnology and healthcare.

We know that downstream process of lactic acid can accounts for 40 to 70% of the production cost (source Kumar and all, Bioresource technology, 2020). That’s why we use years of R&D and industrial expertise to develop adapted purification processes insisting on:

- Less chemical consumption.

- CAPEX/OPEX optimization.

- Reduced development time.

- Minimized scale up risks.

Biomass sugar

Biomass sugar

production

Improve your base production process.

Cellulosic sugars can be extracted from various sources such as wheat straw, paper pulp processes, corn stover, cane bagasse, hardwood or softwood. These sugars can be used as carbon sources for fermentation processes or as raw materials for further transformation into building blocks.

Cellulosic sugars include:

- C5 sugar monomers : xylose, arabinose, etc.

- C6 sugar monomers: mannose, glucose, fructose, galactose, etc.

- Multiple oligosaccharides.

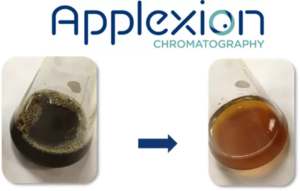

Whatever the nature of the feedstock and the treatment applied, a purification step as a downstream treatment is mandatory to obtain purified sugars. This purification requires high final purity, effective elimination of salts and organic acids but also color removal. As the top priority quality, the downstream process has to present a low environmental footprint, be continuous and productive, as well as robust and cost efficient. Because of feed nature, the process has to be able to handle feed variation.

We propose our chromatography technology to go until purified sugars. Based on historical knowledge and results of years of biomass experience and development we use our chromatography technology as the earth of the purification process. Chromatography step is powerful with an appropriate pretreatment step. It permit to protect chromatography step from specific risks and to fully optimized the chromatography potential.

Working with Applexion:

- Widest experience in the industry.

- Analytical capacities force.

- Project definition, development and execution secured.

- Partners networks to efficiency combine multi-technology process line.