Build your turnkey process

for food ingredients purification

The industrial production of food ingredients and its related food “commodities” ingredients is a sector that faces a myriad of challenges due to the diversity of contexts worldwide.Some regions of the world are still in need of building large capacities, due to demographic and urbanization trends, while others are more facing with modernization and diversification trends.

Modernization of existing plants, often running for several decades, follows different targets for which Applexion has specific offers:

- Decarbonation of processes, through efficiency and electrification.

- Diversification of products, following the development of healthier diets, lower carbon impact foods, and bio-based chemicals for no-food applications.

- Regulations on food safety, quality standard, and water savings.

Evolution of technologies, through digitalization, data science and modelling, have drastically changed our ways of working, the efficiency of our processes, and the level of service we can provide everyday to serve these challenges.

With years of presence in this market, Applexion has developed design effective technologies, processes and a unique application expertise to support our customers on your day to day production.

Applexion offers to support your daily production of food ingredients in all regions, through our Design and Build, Run & Perform, and Upgrade & Revamp program.

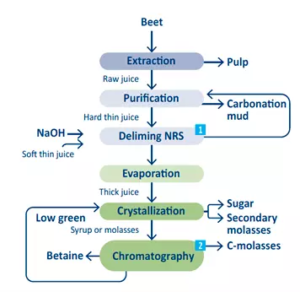

Beet Sugar

Saccharose production

from sugar beet

Improve the production process of your beet sugar factory.

- Cost-effective processes to produce higher quality sugar with better recovery

- Green processes, such as our Applexion™ NRS original juice deliming process

- Increase of the sugar yield from 85% to 95% thanks to our chromatography process, which also yields value-adding by-products

Applexion™ has developed and implemented solutions for the improvement of your base process:

- Applexion™ NRS: this powerful ion exchange process for thin juice deliming is an ideal complement to the liming carbonation process.

- An innovative continuous chromatography step for molasses separation that is an ideal complement to the crystallization process.

Get a better deliming system with NRS process.

With traditional beet sugar production process, the recovery yield, sugar purity and energy consumption are all impacted by the residual calcium in the purified juice.

Applexion™ NRS contributes to the improvement of both evaporator efficiency and sugar quality by producing low-Ca thin juice and reducing sugar turbidity.

Specific benefits of NRS process:

- Easy to operate and very reliable process.

- Inexpensive, robust strong cationic resins.

- Truly green process:

- no effluent production.

- no water/acid consumption.

- no sugar loss.

- no risk of sucrose inversion.

- no juice dilution.

- no evaporator conditions fluctuations.

Valorize all your chromatography fractions and get more revenue sources.

Applexion™ chromatography allows the fractionation of three valuable fractions:

- Sucrose extract is the most valuable fraction from chromatography separation. It is then crystallized to recover approx. 10% additional sugar-in-the-bags.

- Natural betaine is valorized and produced at a purity of 50% to 75%.

- Raffinate containing the rest of non-sugar, currently used as animal feed, fertilizer or beet pulp coating.

Consequently, 3 fractions continuous chromatography is an eco-friendly solution for:

- Higher recovery of sugar: up to 95% yield.

- Expansion projects and green field sugar factories avoiding the need of C-crystallization.

- Betaine recovery from bioethanol vinasses.

Cane sugar

Saccharose production

from sugar cane

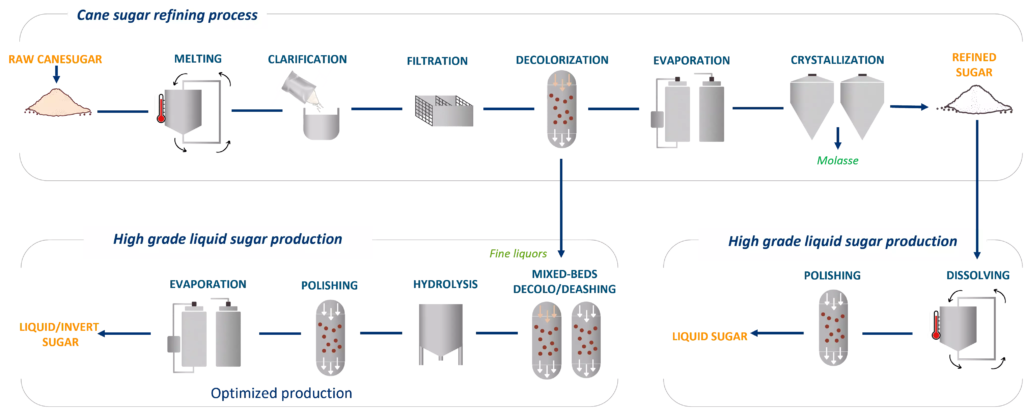

Improve your base production process for your cane sugar operation.

Optimized and cost-effective ultrafiltration and ion-exchange processes for a better performance of your mill and refinery:

- Cane sugar stand-alone refineries and higher quality sugar directly at the mill.

- Added-value with the integration of a line producing specific liquid sugar from fine liquors in the main refinery process.

- Guaranteed CAPEX vs OPEX optimization with Applexion™ decolorization systems.

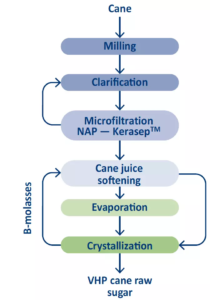

Produce VHP sugar without sulfitation.

Applexion has developed NAP microfiltration processes (New Applexion™ Processes), which allows you to produce a higher quality sugar directly at your mill.

The NAP microfiltration of clarified cane juice, combined with both cane juice softening and crystallization, enables you to produce VHP (Very High Polarization) cane raw sugar, without sulfitation:

- 40% less color.

- 55% less ash.

- 20% higher crystallization speed.

With microfiltered and softened cane juice, evaporators consume less energy and more bagasse is available for co-generation.

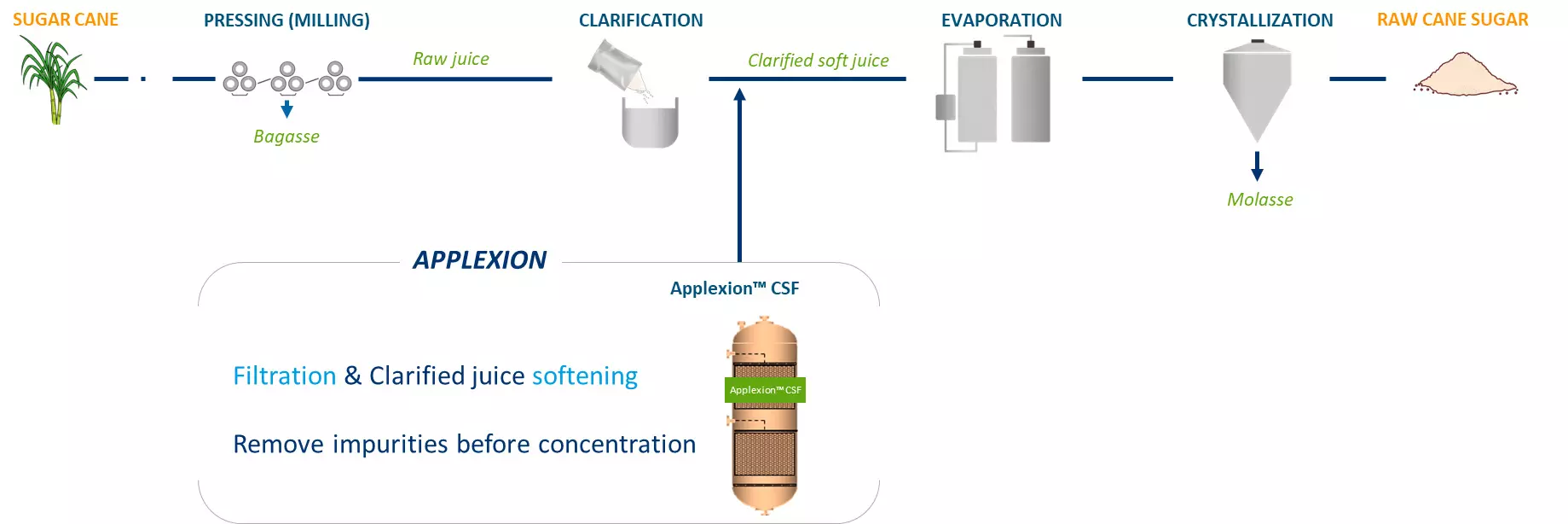

Improve the cane sugar mill process.

Applexion has developed Applexion™ CSF process, a combination of filtration & resin softening in order to remove impurities before concentration.

By reducing salts impurities before evaporation, significantly reduce precipitation during evaporation and improve crystallization process.

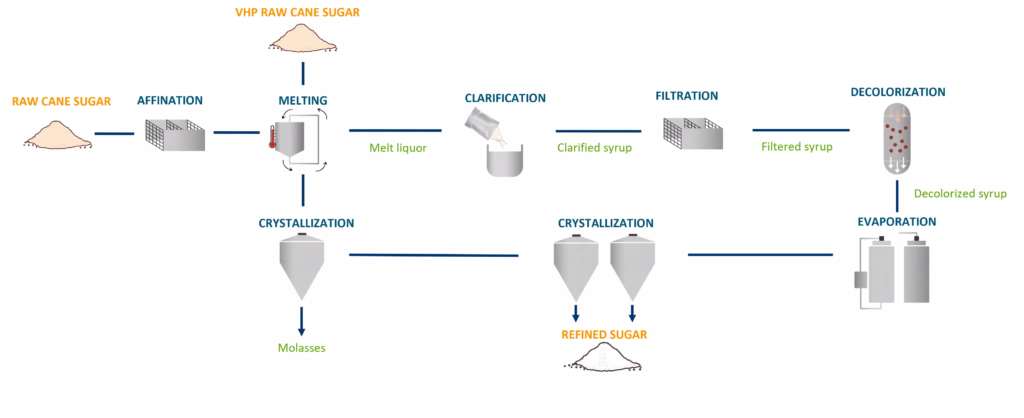

Your cane sugar stand-alone refinery with our decolorization system options.

For cane sugar refineries, decolorization is one of the most critical steps. Our efficient ion-exchange decolorization systems allow a lower resin inventory and savings on both regenerant and water consumption.

Highlight on modernized decolorization process based on ion exchange resin and nanofiltration

- Improved & efficient sequential (IEX).

- New & redesign regeneration process (NF).

Thanks to several innovative regeneration process options, optimize your CAPEX vs OPEX strategy for your IEX decolorization system:

- Nanofiltration Brine Recovery System: reduces by 30% the resin regeneration cost

- Brine Evaporator System: reduces drastically NaCl consumption and regeneration effluents

With no less than 40 000 tons of refined sugar produced every day using Applexion technology, trust the world leader of sugar decolorization by ion exchange.

And what about high quality liquid sugar for more market opportunities?

Produce directly liquid sugar from decolorized fine liquor, concurrently with crystalline refined sugar and get new development strategies.

Applexion’s process by-passes crystallization for a fraction of the production and enables you to produce liquid sugar specifically for local markets or beverage industry, optimizing costs and time-to-market:

- Flexibility in balancing the production of crystalline refined sugar and liquid sugar, according to your strategy (season, customers’ needs…).

- Higher value product for specific local market.

- Cost-effective expansion of an existing refinery:

- Without any modification of the sugar house.

- Without generating additional refinery molasses.

- Parallel processing of fine liquor for producing refined sugar and liquid sugar.

Dairy

Lactose production

from Dairy

Competitive processes for whey demineralization.

Upgrade your base production process to the most competitive level.

- Flexible processes adjusted to your targeted capacity for multiple grades (D30, D50, D70 and D90) and for all types of whey.

- High-performance: higher productivity than with traditional processes, and better recovery yield, guaranteed.

- Costs effective and higher sustainability with our partner electrodialysis (ED) membranes providing significant savings. Our processes allow operating costs, chemical use and energy consumption to be substantially reduced.

Our process solutions are optimized in order to maximize ROI while allowing the most competitive production costs:

- Optimized combination of technologies and processes.

- Guaranteed lifetime of NF/RO membranes, ion-exchange resins.

- Maximum throughput from processing equipment.

- Water recycling in the purification process, in order to reduce fresh water requirements and effluents.

High-efficiency processes for lactose production.

Improve your traditional process line with advanced technologies.

The implementation of innovative digital tools allows to efficiently monitor the processes and enables to enhance quality of production, to save time from operators to managers, to minimize maintenance needs, to optimize the production and to consequently reduce effluent load.

Get better quality and higher yield for:

- Edible lactose.

- Pure liquid lactose syrup with yields up to 97%.

- Refined/pharma lactose grade.

- Valuable lactose derivatives.

Reduce your costs and footprint:

- Chemical-free demineralization of UF whey permeates and resin regeneration.

- Reduced use of anti-scaling and acid cleaning agents on downstream evaporators.

Crystalline lactose: Get a lactose purity up to 99% and target a refined or pharma grade lactose with a single step cooling crystallization.

Edible lactose: a premium quality lactose obtained by Applexion chemical free demineralization of UF whey permeate. Up to 70% monovalent salts removal in NF soft permeate. Permit to increase the lactose purity in the crystallizers up to 5%.

High yield lactose production: Significantly increase your lactose yield from 70% to 90-95% using our Applexion™ SC technology.

Lactose syrup and valuable lactose derivatives: The purification of UF whey permeate into liquid lactose syrup offers an attractive alternative for the production of:

- High purity GOS

- Glucose/ Galactose

- Tagatose, Lactulose, Lactitol…

UF whey permeate softening: Applexion offers a patented, innovative approach to avoid salt precipitation (CaPO3) which consists in converting divalent ions (Ca2+ and PO42-) into more soluble monovalent ions. This salt conversion removes 90% of Ca2+ while a traditional cationic salt conversion removes only 70-75%.

Optimizes purification processes for milk derivatives.

Your benefits with our processes.

- Cost-effective: Increase of both productivity and purity of your targeted products to maximize your return on investment

- Versatility and quality: A wide range of high efficiency purification technologies and FDA-approved membranes and filtration modules

- Eco-friendly: Significant reduction of both chemical and water consumption; by-product valorization

Fractionation of milk components by filtration technologies

With Kerasep™ membrane filtration technology, you get robust and highly reliable solutions to fractionate your milk components, recovered either in the retentate or the permeate. This technology can be used to treat whole or skim milk, raw or pasteurized, and for all concentration targets.

| Component | Reverse Osmosis | Nanofiltration | Ultrafiltration | Microfiltration |

| Whey proteins | Retentate | Retentate | Retentate | Retentate/Permeate |

| Ash | Retentate | Retentate/Permeate | Permeate | Permeate |

| Casein | Retentate | Retentate | Retentate | Retentate |

| Fat | Retentate | Retentate | Retentate | Retentate |

| Lactose | Retentate | Retentate | Permeate | Permeate |

The Kerasep® technology is fully adapted to industrial operations with a 6-year guarantee in 24/7 operations in batch or continuous mode.

Whey proteins recovery and skim milk fractionation.

By combining microfiltration and ultrafiltration, we can provide a turnkey solution to recover Whey Protein Isolates (WPI) from whey. Skim milk can also be fractionated into Milk Protein Concentrate (MPC), Whey Protein Concentrate (WPC), and whey ultrafiltration permeate. Going further, Applexion offers several processes to produce demineralized whey for D30-D90, using smart combination of Applexion™ ion exchange technology and electrodialysis.

Access to various lactose grades and derivatives.

Applexion has developed several processes for the production of:

- Edible lactose.

- Premium crystalline lactose.

- Pharma grade crystalline lactose.

- Lactose syrup

- Lactose derivatives: lactulose, lactitol, tagatose, galactose, etc.

- Galacto-oligosaccharides (GOS) or transgalacto-olisaccharides (TOS) from lactose.

- Milk proteins: lactoferrin, alpha-lactalbumin, beta-lactoglobulin, lactoperoxidase, etc.

Please check our lactose process page to learn more about our innovative industrial solutions.

Starch sweeteners

Saccharose production

from starch sweeteners

Improve your process or adopt the most competitive production process.

Whether you need a single unit, a combination of several unit operations to improve your base process or a complete, turnkey process line including up to 25 combined units, we can help you overcome all your challenges:

- Optimize OPEX and CAPEX according to your specific constraints (energy type and costs, product specifications, etc…)

- Produce high and stable quality sweeteners from a wide range of starch raw materials (e.g. corn, wheat, potatoes, cassava, etc.).

Compact, robust & eco-Friendly process lines for the production of:

- Acid-converted glucose syrup.

- Low DE glucose syrups.

- High DE glucose syrups.

- Maltose syrups

- HFS 42, HFS 55, HFS 90.

- Crystalline dextrose / fructose through our cooperation with BMA (world leader in this technology).

- Polyols (sorbitol, mannitol…).

- Oligosaccharides.

- Fructose syrups.

Produce glucose syrups from any food grade native starch.

Flexible

From any sources of starch, this simple process line enables you to produce any of the following:

- High maltose syrups and high DE glucose syrups using two simple, free enzymes for liquefaction and saccharification.

- Low DE glucose syrups using more complex enzymatic cocktails for the saccharification step.

Green and cost-effective

Steps 1 & 2

We help you to find the best enzymes for both conversion steps, liquefaction and saccharification.

Step 3

Our Kerasep™ ceramic membranes minimize or eliminate consumption of filtering aids and activated powdered carbon, and reduce effluent production and manpower. The soluble proteins are eliminated by microfiltration, reducing the costs of further refining. The microfiltration retentate, enriched in proteins and fat, can be recycled and valorized as a co-product in the corn wet milling process.

Step 4

Our highly-efficient and compact up-flow ion-exchange demineralization and decolorization systems provide you with a better quality of final product and a lower consumption of chemicals, water and resin.

Step 5

Thanks to an optimum use of the compact multiple effects plate & frame or tubular evaporators, the recolorization of the purified syrups is minimized: the quality is thus preserved during storage and shipping.

Diversify your revenues with HFS from glucose syrups.

High-Fructose Syrup (HFS) – also called Isoglucose, is a group of starch-based sweeteners produced by converting glucose into fructose to produce the desired sweetness. It is typically used as sugar substitute and is ubiquitous in processed foods and beverages.

- HFS42 is used in many foods and baked goods.

- HFS55 is mostly used in soft drinks.

- HFS90, sweeter than sucrose, is primarily mixed with HFS42 to make HFS55 but also used in small quantities for specialty applications.

Applexion designs and implements your processes according to High Fructose Syrup 42 and 55, Quality Guidelines and Analytical Procedures, from ISBT (International Society of Beverage Technologists), which have been developed by major producers and end-users.

Our continuous chromatography separation system Applexion™ SSMB (Sequential Simulated Moving Bed) provides lower water and resin requirements and increased glucose/fructose separation performance.

SSMB can also be used for other separations: enrichment of dextrose, maltose, polyols separation, etc.

With more than 70 projects successfully completed worldwide, trust the efficiency of our processes to enlarge your opportunities.