Adapt the downstream process

to meet your production goals

Some industrial products are key in the current time of industry evolution, and they require cutting edge purification technologies!

At Applexion, for +50 years, we have developed and addressed a huge diversity of special application, from lab to large scale. Probably more than any others in these technologies. This is why, together with technology leaders for some industrial products, we are developing specific and cutting edge purification solutions using Applexion technologies.

hydrometallurgy

Hydrometallurgy production

Li and rare earths.

Improve the production process.

In 2024, Applexion has entered into an exclusive partnership with Seprosys, in the field of purification applied to hydrometallurgy streams. Seprosys has developed a strong knowledge background in hydrometallurgy field in the last 15 years, focusing its efforts on purification of energy transition metals. Their developments are based on proven technologies and reliable methods facilitating industrial scale-up. With teams based in La Rochelle (France), Seprosys manages up to 20 different projects a year, from process discovery, proof of concept validation to pilot plant scale-up.

Hydrometallurgy sector, notably through the drastic increase of Lithium and other metallic compounds needs, sourced from direct extraction, geothermal drilling wells or recycled from previous uses, is facing key environmental and purification challenges while world is progressing in energy and mobility transition.

Supported by innovative digital tools which secure implementation of Direct Lithium Extraction and optimize development steps, Seprosys and Applexion offer separation solutions for each stage:

• lithium enrichment from initial diluted brines, based upon use of highly selective sorbents and patented capture technology

• concentration of lithium streams (water removal is based upon nanofiltration and reverse osmosis membrane technology)

• polishing of lithium concentrate, thanks to the removal of divalent cationic load and foreign metallic impurities

Applexion will ensure scale-up and industrialization of Seprosys proven processes, both in Direct Lithium Extraction and in energetic metal separation and recycling, especially when coming from black mass treatment. Those processes can be adapted and specially designed when production of additional metallic compounds aside lithium is sought, such as nickel, manganese, copper or cobalt.

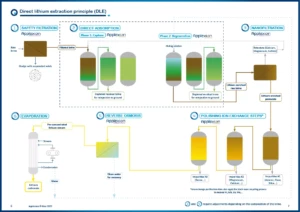

Direct Lithium extraction principle (DLE).

The Direct Lithium Extraction (DLE) process offers a cleaner, faster and more selective alternative to traditional evaporation methods. Designed for both primary and recycled lithium sources, it enables the recovery of high purity lithium with reduced environmental impact.

In partnership with Seprosys, Applexion provides turnkey DLE solutions that are tailored according to raw material composition, energy sources, site constraints and desired end product purity.

Main stages of the process:

![]() Pre-treatment: Conditioning and clarification of the raw feed (e.g., brine or leachate) to remove unwantedsolids (suspended solids and colloids).

Pre-treatment: Conditioning and clarification of the raw feed (e.g., brine or leachate) to remove unwantedsolids (suspended solids and colloids).

![]() Selective extraction – step 1

Selective extraction – step 1

Lithium ions are captured using tailored materials (adsorbents or ion-exchange resins) depending on the feed profile.

Washing & elution – step 2

Lithium is released from the extraction media and concentrated using a controlled elution step.

![]() Purification & polishing

Purification & polishing

Removal of co-extracted impurities (e.g., calcium, magnesium, boron) to meet battery-gradestandards.

![]() Concentration & crystallization

Concentration & crystallization

Final concentration of lithium into LiOH or Li₂CO₃, ready for downstream battery productionor conversion units.

Key performance features:

- High lithium recovery rate: up to 90% depending on feed quality

- No need for large evaporation ponds: faster, lower-impact operations

- Selective recovery: optimized for lithium with minimal reagent use

- Adaptable configuration: sorbents, membranes or resins, based on feed type

- Compact & modular units: scalable for pilot to industrial scale

- Low water and energy consumption: smart design for sustainability

- Data-driven monitoring: enabled by Applexion digital solutions

(Run 4.0 – Link 4.0)

Specialty chemicals

Specialty chemicals

production

Improve your base production process.

Applexion is involved in the development of industrial purification processes for chemical intermediates.

Applexion™ SC (sequential chromatography), Applexion™ ion exchange and adsorption provide clients with industrial robust solution to decolorization, desalting and purification.

Applexion™ SC (sequential chromatography) enables to achieve the highest level of purity of the target molecule in the field of fractionation and enrichment.

Kerasep™ filtration systems and membranes are the industrial reference for clarification and concentration processes.

Phosphoric Acid

Phosphoric acid production

Upgrade your base production process to the most competitive level.

The industrial phosphoric acid solution contains minor elements, such as Fe, Al, Mg and heavy metals such as Cd. These impurities can be removed by Applexion™ Ion exchange technology. Many innovative developments have been performed by Applexion™ in relation with ion exchange technology, especially to remove mineral impurities present in very small quantities. Indeed, even showing residual traces, these minute impurities can be very detrimental to final product quality, impairing its sought properties.

In order to optimize economics and to reduce environmental impact of industrial systems, continuous ion exchange technology is one of the most suitable solutions which provides significant benefits such as final purity level and effluent recycling. Combined with nanofiltration and reverse osmosis units, a very significant amount of water can be reused, saving massive amounts of fresh water.

When deploying continuous Ion Exchange system, Applexion™ will help you select the best resins, guaranteeing optimal balance between day-to-day performance and prolonged shelf-life.