Upgrade & Revamp

Let’s make your historic process line

a new state of the art one

and boost your savings.

Make savings by modernizing your process line.

- Save up to 50% in production costs.

- Increase by 5 to 10% your annual capacity.

- Stop production downtime for maintenance.

This is for You, if You’re

Plant director

And you want to save up to 50% of cost and greenhouse emissions by boosting the purification performances of your systems:

- Add our Performance Boosters to your processes. Save from 30 to 100% on water & utilities usage.

- Benchmark solutions with sustainability and economics criteria.

- Full Carbon footprint of your project, Scope 1, 2 and 3.

- Unique set of Industry 4.0 services for optimal production every day.

Technical supervisor

And you want to optimize productivity by carrying out maintenance without production downtime:

- Increase agility of your system so that it never stops, even when maintenance is required.

- Benefit from latest state of the art design and fabrication for your pressure vessels change outs.

- Benefit from latest state of the art programs during your automation upgrades.

Operator & process specialist

And you want to gain in expertise and control of your equipment, wherever you are, whoever you are :

- Be aware of current status of every system you have in charge in real time and in no time. Focus on when and where you are needed the most.

- Follow and/or challenge our real-time assessment and recommendations to optimize your everyday production and non-routine challenges.

- Audit, troubleshoot and remedy to system early appearing inefficiency from wherever you are.

- Benchmark, test and analyze the performances of your systems across multiple units, multiple plants and compared to Applexion reference.

Tell us about your challenges

If you look how to further optimize productivity, reduce your carbon footprint, make savings and improve your return on investment, let’s work together!

Upgrade your process

Your installation modernization

will allow you to reduce your carbon footprint

Maintenance without production downtime

nor operating swings

Decolorization upgrading solution

to optimize costs and carbon footprint

Ceramic filtration upgrade

to decrease utilities consumption

Utilities saving solutions

to optimize costs and carbon footprint

New column design

to extend purification lines lifetime

Upgrade your process

Maintenance

without production downtime nor operating swings

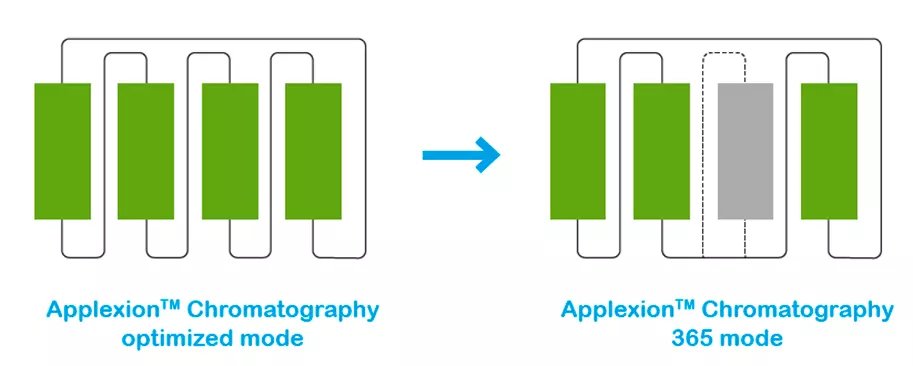

The principle of 365 Boost consists in isolating one part of the system from the production stream while it is being serviced. The other parts continue to produce although in slightly degraded mode. Once the isolated part is ready for production, the system will return back to its nominal production mode. The 365 Boost package enables production to continue even if one cell is shut down for maintenance.

- Allows to stay in production while the system is under maintenance.

- Keep at least 75% of the capacity and aim for a possibly up to 10% annual capacity increase.

- Take action when you need, not when you can.

- No stop during production campaign.

- Especially during high production demand period.

- Take action when you need, not when you can.

- Backwash possibility without waiting the annual shutdown.

- Intervention less stressful.

- Cost savings.

- Capacity optimized.

- Improve overall system condition.

- Reduce pressure drop.

- Reduce pressure alarm.

- Reduce operator manual intervention.

- Easily participate to maintain the good shape of the installation in the aim to maintain the performances.

- As a result of Boost 365 you will possibly be able to reach up to 10% annual capacity increase, according to maintenance requirements and local operating conditions.

Benefits of 365 Boost

- Uninterrupted production.

- Flexible maintenance.

- Stabilized system conditions.

- Easy to implement.

- Revenue boost and it is easy to implement.

Stop production downtime for maintenance :

Upgrade your process

Decolorization upgrading solution

to optimize costs and carbon footprint

Ion exchange implementation requires sustainable operation and robust performance. Design cannot be disconnected from a minimal use of caustic brine, chemicals, water and the production of regeneration effluent.

In order to optimize costs, reduce these consumption and reduce carbon footprint, Applexion offers a modernized decolorization process based on best ion exchange resin selection and membrane filtration implementation, including two steps:

- Improved and efficient ion exchange.

- Advanced brine recovery system.

Our modernization solution reduces fresh water and brine usage and drastically minimizes effluent. It also optimizes your profitability and helps you meet stricter environmental regulations, notably with a significant reduction of the carbon footprint.

- Upgrade process efficiency.

- Collect & reuse fractions.

- Decrease regeneration consumption.

- Reduce carbon footprint.

Benefits of Decolo Boost

- Environmental footprint reduction.

- OPEX reduction.

- Chemical use reduction.

- Effluent reduction.

- Fresh water savings.

To see your future savings :

Upgrade your process

Ceramic filtration system upgrade

to decrease utilities consumption

To meet the new industrial challenges, Filter Boost allows you recovering and recycling utilities on membrane filtration system. The basics : recycle water, chemicals and energy during Cleaning In Place (CIP).

- Choose a “do better” solution to upgrade your filtration system.

- Redesign Cleaning In Place (CIP) process.

- Adjust Membrane Design to your needs.

Thanks to this upgrade, you will optimize chemical and water consumption by implementing a recycling routine for CIP solutions and steam (and energy) consumption by recovering heat from other hot liquids.

Benefits of Filter Boost

- Energy savings.

- Non-stop configuration.

- Chemical use reduction.

- Effluent reduction.

- OPEX reduction.

- Increase production.

Reduce your carbon footprint & make savings :

Upgrade your process

Utilities saving solutions

to optimize costs and carbon footprint

Challenges are evolving in the industrial sector: water resources are limited, chemical prices and effluents treatment costs are increasing, and environmental regulations are becoming every day more strict.

In this context, Applexion offers two ways to reduce costs and carbon footprint:

- Reduce chemical consumption, wastewater production, fresh water consumption and operating costs by recycling fractions and reusing them for the next regeneration cycle.

- Change in chemical product may also contribute to the OPEX reduction, as well as purification and environment performances improvement.

Some designs enable you to reduce fresh chemicals and water consumption down by 40% simply thanks to recycling part of the effluent fractions. It helps you reduce your effluent volume without compromising your product quality nor separation performances.

Simple! And performance lies in the details:

- Keep the process efficiency untouched

- Collect & reuse fractions

- Decrease reactants consumption with optimized regeneration steps

Benefits of Recycle Boost

- Water reducing.

- OPEX reduction.

- Effluent reduction.

- Chemical use reduction.

Make savings by recycling and reusing effluent fractions :

Upgrade your process

New column design

to extend purification lines lifetime

Applexion has designed and commissioned more than 1,200 columns over the last years throughout the globe. Thanks to this unique experience and numerous shared feedback by our customers, we have identified two areas of improvement: the corrosion protection damages on sharp and constrained areas, and the fluid distribution network maintenance, which could be difficult in number of cases overtime. Applexion offers you a cutting-edge design of column, that is much simple with improved cleanability and easier maintenance. It results in a much longer column lifetime.

When is a column replacement necessary?

The most important criteria to consider is the condition of the column. Is the steel and corrosion protection still in good condition?

After several decades of production, the columns are aging and may need some repair or complete replacement. On the other hand, the customer’s production recipe and feed may be different from the commissioning phase. Thus, a design optimization may be useful.

Benefits of Redesign Boost

- Reliable design.

- Extended lifetime.

- Easier maintenance.

- Better cleanability.

- Revenue boost.

Improve return on investment thanks to extended column lifetime :

Upgrade & Revamp

Our resources

Why choose Applexion?

and offering on Chromatography, Ion exchange and Membrane filtration technologies.

The only global player, all over the world and all over the life cycle of your equipment.

You have a new one to share?

Frequently Asked Questions

What is your plan of reduction of Carbon emissions?

Our findings show that most of the carbon emissions to be saved is by the optimization of the operation of the system and of its integration in the overall process. This is why we have designed our Performance Boosters and our unique set of Industry 4.0 services. Their targets is to tackle +800,000 tons of CO2 eq emission per year through optimizing existing manufacturing assets. Specific saving case with sustainability and economics criteria are studied and provided on a need be cases.

Does 365 Boost require a lot of modification in order to avoid downtime during maintenance?

No, 365 Boost is easy to implement in a very large number of existing system design. No additional space is required, no additional resin or column to be foreseen. With this Performance booster implemented, your production is always uninterrupted. You gain flexibility in your maintenance planning where all exceptional steps, such as resin backwash or resin and membrane change outs can be done without waiting the annual shutdown, and even during the high production season. Intervention is therefore less stressful and overall productivity of the system is improved, especially when it matters the most.

Are my performance boosters decreasing carbon emissions ?

Yes of course, and that is a big point of it. Carbon emission are often reduced to energy, all activity data are source of carbon emission: Transportation, the material itself (product, utility), effluents… For each activity data, there is an emission factor. For example, a ton of Caustic Soda (NaOH) accounts for 1.2 tons of CO2 eq; and a ton of waste water accounts for 300kg of CO2eq.

Applexion Performance Boosters focus on reducing utilities consumption, in a range from 30 to 100%. In some cases, a change in utility type, with less CO2eq content, is also a great solution. Their targets is to tackle +800,000 tons of CO2 eq emission per year through optimizing your production every day. Specific saving case with sustainability and economics criteria are studied and provided on a need be cases.